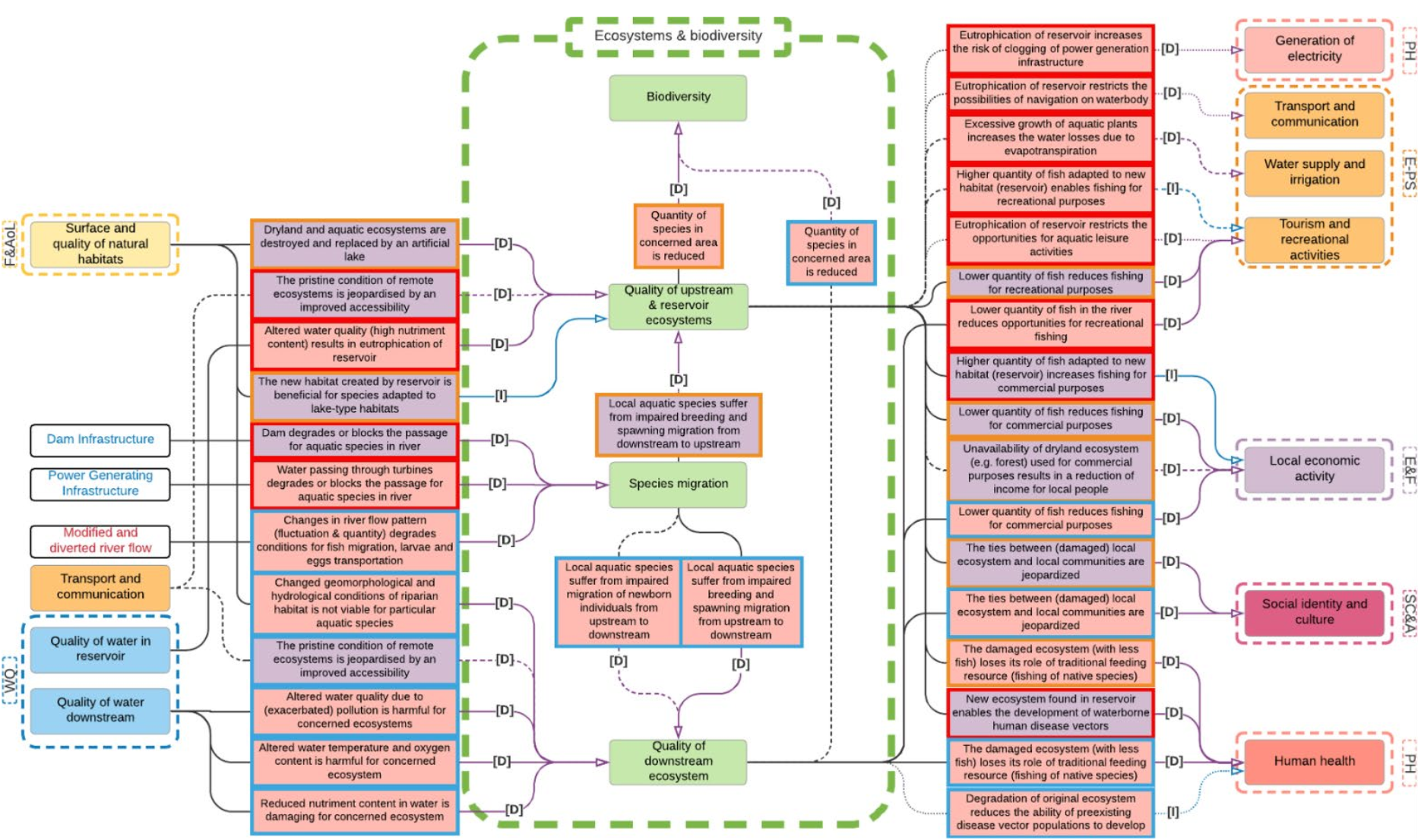

Hydropower plants are able to produce low-carbon electricity during their service life. To maintain or extend their initial lifetime, refurbishment actions can occur to retrofit and modernise existing hydropower plants. Quantifying the environmental performance of these actions is important to minimise the impacts of the hydropower systems.

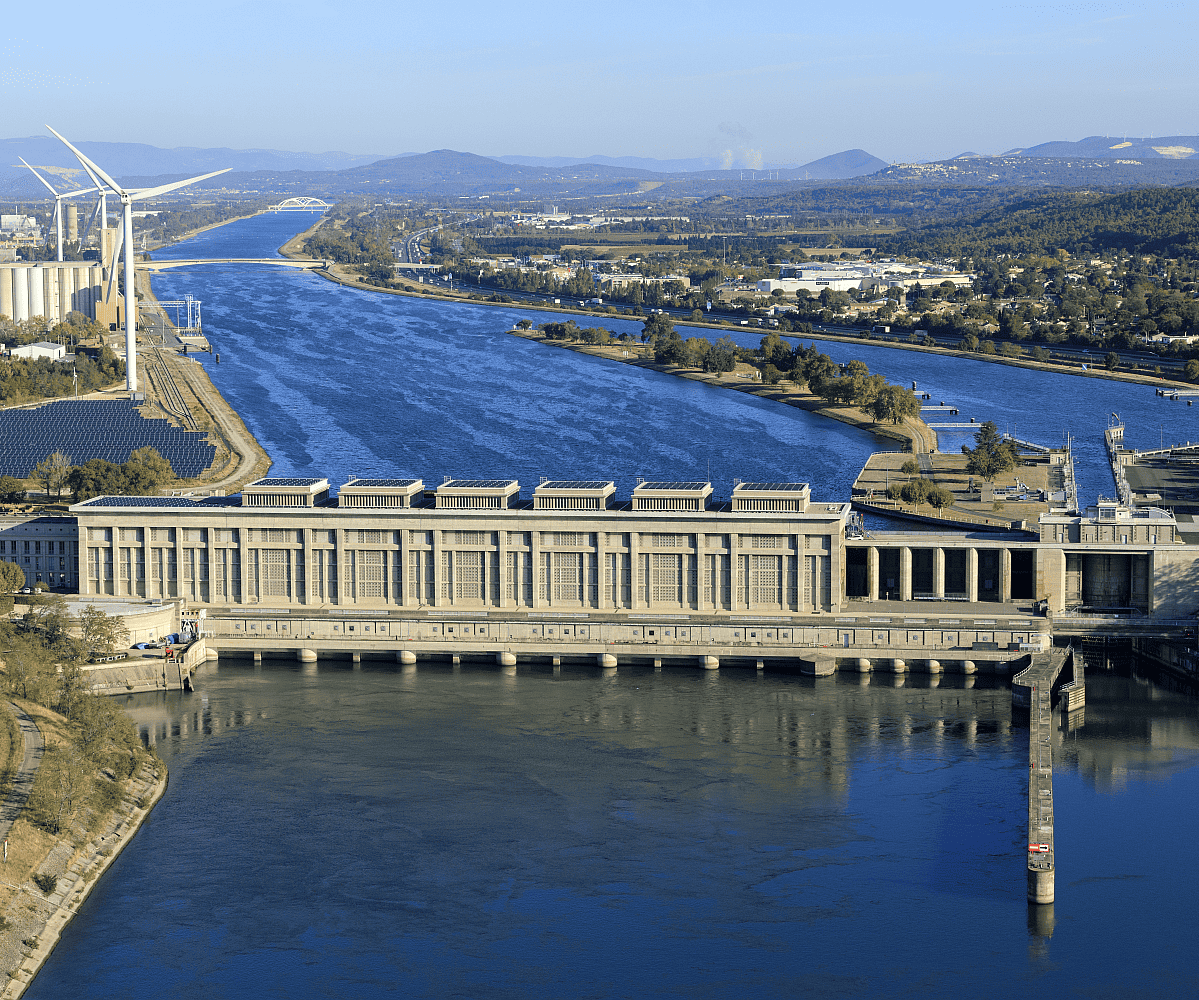

To evaluate these impacts in a consistent way, the ReHydro project applies Life Cycle Assessment (LCA), a standardised methodology to quantify potential environmental impacts. In the context of Work Package 5, an LCA study is carried out on one of our demonstration sites owned by our partner CNR (Compagnie Nationale du Rhône) near Caderousse. Two refurbishment actions of this run-of-river hydropower plant have been proposed by CNR and ENGIE tailored to the demonstration sites’ needs:

- The construction of a new fish ladder to ease the passage of different fish species.

- The construction of a Small Hydropower Plant (SHPP) to compensate for the producible loss occurring due to a French regulation, which mandated an increase of the environmental flow (water dedicated purely to the ecosystem) and thus a decrease of the water available for hydropower production.

These different actions were integrated in scenarios that will be thoroughly examined via the LCA-study to understand their environmental impacts. The final deliverable will include the complete LCA analysis of these scenarios and is expected in October 2026.

You can find the full paper in our knowledge hub!