For the past months, our partners working on the business side of ReHydro have conducted a survey aimed at hydropower professionals across Europe, focusing on hydropower modernisation within the European hydropower fleet, to better understand the key drivers behind modernisation efforts and to identify the main barriers faced by the sector.

The survey was rolled out in three phases: Phase one focused on internal surveying among the ReHydro project partners, phase two gathered data from a number of select hydropower operators, and phase three opened the survey up to the public and any relevant hydropower plant personnel that would help us close any remaining gaps in knowledge.

All three phases have been completed within the first quarter of 2025. On April 11th, a workshop was held with many of the survey’s participants to discuss and finalise conclusions. Viewing the results within specific contexts was also made possible through the direct dialogue with participants.

We were able to obtain responses from companies representing 121 GW, about half of the European hydropower fleet, gathering information from 34 individual companies of all sizes. These utilities are geographically representative of all of Europe, which provides us with solid data to align our research focus with the needs of the hydropower sector.

The survey led us to three key conclusions:

- About a quarter of the European hydropower fleet was partially modernised within the past ten years.

- The main trigger of hydropower modernisation is to make sure assets keep producing electricity, for example, by reducing planned and unplanned downtimes.

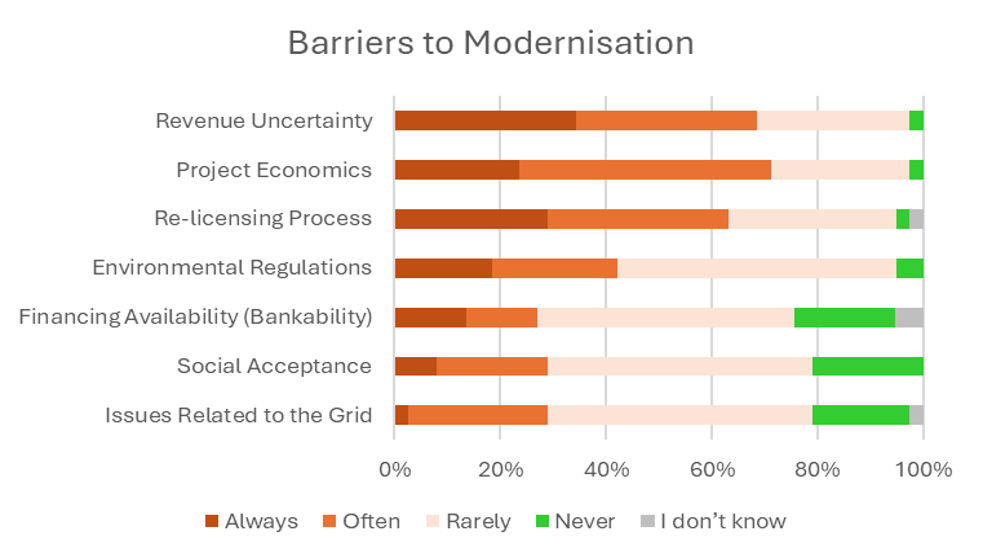

- Uncertainties are the main challenges the sector faces when planning modernisation projects (see graph below).

Going forward, the data we collected will help us align our actions within ReHydro with the needs of the hydropower sector. The workshop held together with the participants also fostered connection and provided contextual insights into the challenges faced by hydropower experts, making for a great first ReHydro-organised event.